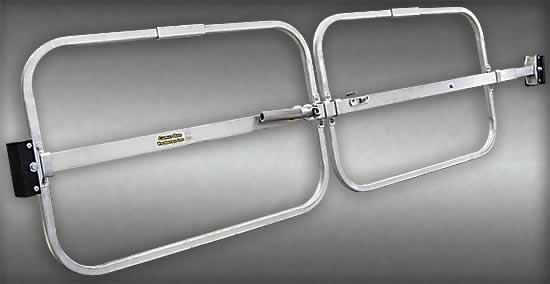

- Range 83″-110″

- Heavy Duty Coil Spring

- Heavy Duty Drive Gear & Locking System

- High Tensile Strength Aluminum Foot with Fitted High Friction Rubber Foot Pad

- 5″ x 3.5″ Foot For Added Surface Area

- Aluminum and Stainless Steel

- No Hydraulics

- Built for the Long Haul

- Pressure Can Be Preset to Prevent punching Holes in Roof of Trailer

- Gear Driven Means No Problems In Freezer

- The Wings & Clamps You Already Have May Fit Our Bar

- Gear System Estimated To Last 5-10 Yrs.

- If Bar Gets Bent You Will Be Able To Convert Drive System Into New Bar In 5 Minutes

- UHMW Tape On Back Of Gear System To Act As Slide & Prevent Metal From Wearing Out

- You Will Be Able To Maintain This Bar, Not Throw It Away

- 5 Yr. Warranty On Drive System Under Normal Use

In a fast paced warehouse operation it’s not uncommon for a towmotor operator to bump a load bar hard enough to bend it. Our commercial load bars can be rebuilt in just a few minutes and back working as smoothly as a new unit.